Heat buffer – convenient heating with cheap fuels

Heat buffers are widely used in Europe. In our country, they remain exotic – unjustly so, because such a device would bring tangible benefits in terms of savings directly in Polish złoty in every coal or wood-heated home. The benefits would also be noticeable outside, in the form of air free from the smell of smoke.

Let’s see how a heat buffer works, what are the installation costs, and the benefits of using it. We will also provide details on the proper construction of a buffer tank, which, contrary to appearances, is not such a strange, giant boiler.

How does a heat buffer work?

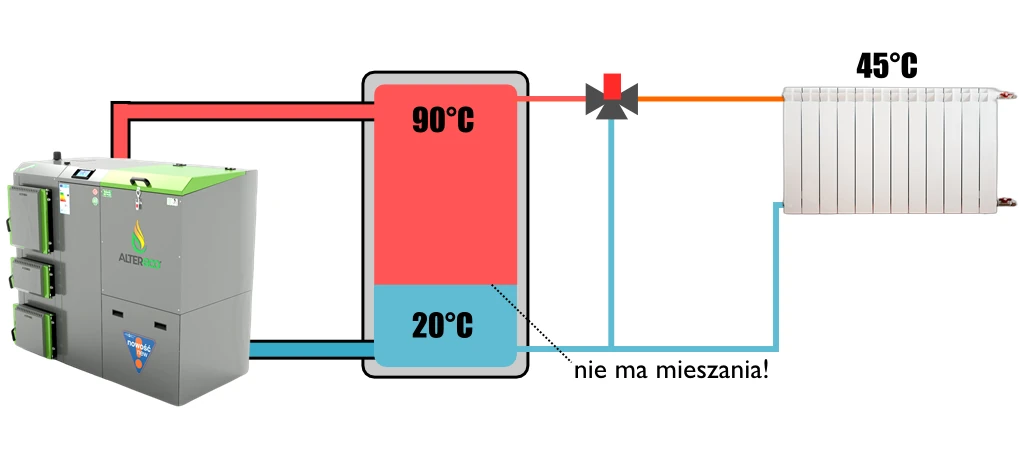

The most important feature of a heat buffer is its layered water arrangement. Hot water is lighter than cold water. Therefore, if a layer of hot water is placed above a layer of cold water, the system will behave like a mixture of water and oil. The layers will not mix, and the hot water will never heat up the cold water from above, even though they are in direct contact. Heating water from the top through contact is impossible. That is why burners on stoves are located beneath the pots.

The above diagram presents the idea of the simplest connection of a heat buffer in a heating system. There are two interconnected but temperature-independent circuits: boiler-buffer and buffer-radiators.

The boiler operates at full power to heat the buffer to 80-90°C. Heating takes several hours, and as a result, the entire tank should be heated to the highest possible temperature. At this point, the boiler stops working, and the next firing will be necessary only when the entire heat supply from the buffer is depleted (usually from one day up to a week, depending on the buffer capacity and weather conditions).

The buffer stores heat with minimal losses and allows it to be withdrawn in any required quantity precisely when needed. An automatic thermostat is preferably installed at the outlet of the buffer, which doses the heat in such a way as to maintain a constant temperature in the house. Building heating control becomes as precise as in the case of gas or electric heating.

Thanks to the layered water arrangement, it is not necessary to heat the entire buffer to a high temperature to extract heat from it. The hottest water is always located at the top of the tank.

Benefits and Issues Summary

A heat buffer makes the boiler clean and low-maintenance – almost like a gas boiler, while allowing the use of inexpensive fuel.

- Clean and efficient combustion – thanks to the boiler operating at full power,

- Infrequent visits to the boiler room – the larger the buffer, the less frequent the visits, usually every couple of days in winter or once a week in summer if only hot water needs to be heated,

- Even temperature in the house – heat from the buffer can be supplied to the building as needed, around the clock.

A heat buffer is more than just a support for the boiler. It is a home heat storage capable of combining functions such as:

- Domestic hot water tank

- Tank for solar collectors

- Heat storage from electricity during off-peak hours

By storing heat in one place, there is no need to buy separate tanks for each of these purposes and waste space on their installation. Storing hot water in one well-insulated tank also results in lower energy losses and, therefore, lower costs.

The buffer tank for heat is simple and durable. It is simple because black steel is sufficient. It is durable because during operation, it only comes into contact with boiler water. It is not subject to the problem of rapid corrosion known from domestic hot water tanks.

The main drawback of a heat buffer is the fact that it occupies space. New, small houses are usually designed independently of the actual requirements (with the intention of using natural gas for heating), so the boiler room is small and has the dimensions of a broom closet. Although the buffer can be placed in a neighboring room, it requires using valuable square meters of space for this purpose.

The price of a buffer tank is also significant. A ready-made simple 1000-liter tank costs around 5000 PLN. Adding a solar coil and domestic hot water (DHW) capabilities increases the price to 6-8 thousand PLN. Fortunately, the price of a buffer can be significantly reduced by purchasing a suitable used tank or having a local professional construct it. However, considering all the benefits of having a heat buffer, even the purchase of a ready-made tank pays off in a few years.

It is a fact that storing hot water in the buffer results in losses, but in the final balance, these losses are acceptable. In a well-insulated buffer, the water temperature should decrease at a rate of about 2-3°C per day for a 1000-liter tank (approximately 1 kWh). Even this amount of heat does not go to waste or escape into thin air but indirectly heats the house.

The simplicity of the construction and operation of a heat buffer does not mean that building

When to use a heat buffer?

It is easier to say when it is not worth using a heat buffer:

- In a large, old, uninsulated house with a large heating system and radiators operating at high temperatures—there, the boiler has a constant heat demand, and a water buffer would need to hold several tons of water to be useful.

- When heating the house with natural gas—this type of heating is controllable and does not require storing energy for later use.

In any other case, using a heat buffer brings versatile benefits. There are situations where a heat buffer becomes essential to prevent heating from becoming a tormenting experience:

- With a gravity-fed boiler in a new house—even the best gravity-fed boilers are not suitable for standalone use in new homes. They cannot efficiently and cleanly heat at the low capacities required by well-insulated modern homes. And the real tragedy begins when they are connected to a system with predominantly underfloor heating. The result is smell, dirt, and wasted life in the boiler room. Connecting a heat buffer eliminates these problems. Currently available class 5 boilers on the market even require connection to a heat buffer, sometimes risking warranty voiding. But even if that is not the case, it is still worth considering a heat buffer because it will be necessary once anti-smog regulations come into effect. Formally, such a boiler meets the requirements of class 5 only when operating at full power, i.e., with a buffer.

- With underfloor heating—the temperature range suitable for solid fuel boilers and underfloor heating does not align, making the collaboration between a gravity-fed boiler and underfloor heating a smoky and smelly nightmare. To reconcile these two worlds, a heat buffer is necessary, enabling efficient combustion in the boiler at high temperatures and stable operation of the underfloor heating at the appropriate low supply temperature.

- With wood gasifying boilers—these boilers are designed to operate only at full power. Of course, no one will insist that a buffer be installed with such a boiler for proud descendants of the Sarmatians! That is why there are those who store wood in them like in an old “trash heap,” and then cry that it rotted, soaked in resin, and after three years, the boiler is a sieve.

How much can you gain?

A properly sized and correctly operated gravity-fed boiler achieves an average heating efficiency of around 50% throughout the year. Incorrect burning, lack of cleaning, excessive nominal power, and insufficient heat exchanger surface area can all cause efficiency to drop to around 30% or even lower.

A boiler working in conjunction with a heat buffer will operate at full power, burning fuel under reasonable conditions and high temperatures. As a result, it will extract as much energy from the fuel as possible, avoid soot buildup, and absorb as much heat as allowed by the heat exchanger.

Fuel savings of around 30-50% are therefore quite realistic, depending on how poorly it was burned before. But even if there were no fuel savings at all, there would still be time saved on boiler room maintenance.

What buffer capacity?

The larger the buffer capacity, the better, of course within reasonable limits and possibilities. A sensible capacity for an average building (around 150m2) is 1000-2000 liters. The capacity of the heat buffer should be determined in relation to the building’s heat demand (which can also be found through calculations on cieplowlasciwie.pl). If possible, it is best to calculate the capacity so that even during the coldest period, the buffer can be charged at worst every 24 hours.

- To roughly determine the maximum heating power demand of your home, use one of the available methods. Let’s assume it is 5kW.

- Multiply this number by 24 hours – you get 120kWh, which represents the maximum daily heat consumption. The thermal capacity of the buffer should be able to accommodate this amount, so that in the worst case, firing the boiler occurs once a day.

- Based on the specific heat of water, we know that 1000 liters of water heated by 60 degrees Celsius (from 30°C to 90°C) can store approximately 65kWh of energy (taking into account rough losses). Therefore, to store around 120kWh, nearly 2000 liters of water will be needed.

- The amount of heat that can be stored and extracted from 1000 liters of water will depend on the maximum water temperature in the buffer and the minimum usable water temperature for heating the building. In the above calculation, optimistic assumptions were made that these temperatures are 90°C and 30°C, respectively. It is advisable to heat the buffer to 90°C, but it also requires proper insulation. On the other hand, the “lower limit of usability” of the water depends on the type of heating system: underfloor heating will perform best, as it can still heat the building with water at 30°C, while radiator systems may deliver insufficient power even with water supplied at 40°C, and in freezing temperatures, even 45-50°C may be too low (depending on the size of the radiators). If the buffer has 30°C water, it will need to be fired up again to reheat it. The smaller the range between these two temperatures, the smaller the thermal capacity of the buffer needs to be and the larger its capacity should be.

- When the buffer is also used for domestic hot water (DHW), it will naturally discharge more quickly. This can be accepted by charging it more frequently or by increasing its capacity. By assuming that DHW is heated to a maximum of 55°C, which is approximately a 45-degree difference from cold tap water, heating 100 liters of DHW will consume about 4.5kWh. This amount of energy is stored in just 70 liters of hot water in the buffer. However, the DHW coil cannot extract this energy in its entirety, so it is safer to assume a ratio of at least 1:1, meaning that heating every 100 liters of DHW will require a minimum of 100 liters of buffer capacity.

If the calculated capacity is too large (due to space limitations or cost of the tank), the buffer can be smaller, for example, 1000 liters in the above case, which means it can store heat needed for at least 24 hours, and during freezing temperatures, it will need to be charged every 12 hours at worst. A smaller buffer still has the advantage of operating at full power, extracting more energy from the same amount of fuel. However, the time between subsequent firing cycles is shortened.

Choice of Tank

The buffer tank must be a vertical tank because that is the only way to maintain stratification of water at different temperatures, which is essential for the buffer’s operation. The most practical and durable shape for the tank is a cylinder. Contrary to intuition, the weight of a few tons of water does not exert such strong pressure to cause a rectangular tank made of a few millimeters thick sheet metal to bulge easily.

Before purchasing or constructing a tank, it is important to consider that it needs to fit into the boiler room. This means that without insulation, it cannot be wider than the doors through which it will be brought in (usually 70-90 cm).

Choice of Boiler

The principles of selecting the boiler power based on the building’s needs when using a buffer tank no longer apply because we are no longer directly heating the building, but rather a large water tank. Therefore, the boiler power can be almost arbitrarily high. The limitation is not so much the boiler power but rather the volume of the combustion chamber.

Without any issues, a boiler with a power of 20-30 kW or even greater can be used. Such a larger boiler can be much cheaper than lower power ones. Oversizing the boiler power compared to the designer’s calculations is not a violation but, on the contrary, brings tangible benefits.

Construction of the System with a Buffer Tank

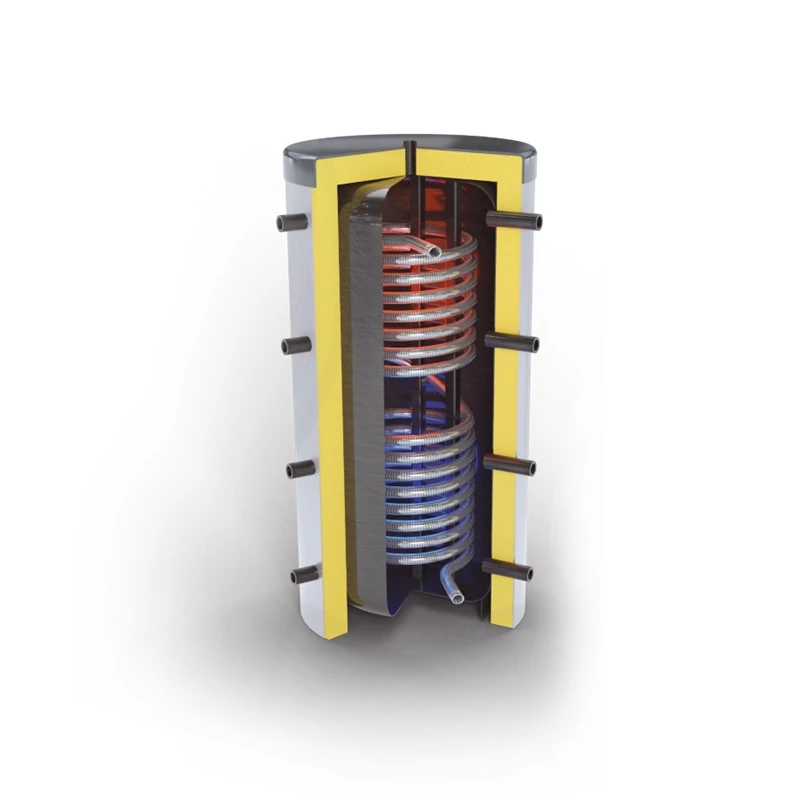

The complexity of the system with a buffer tank and the internal structure of the buffer tank itself depend on the types and quantity of heat sources it will be supplied with.

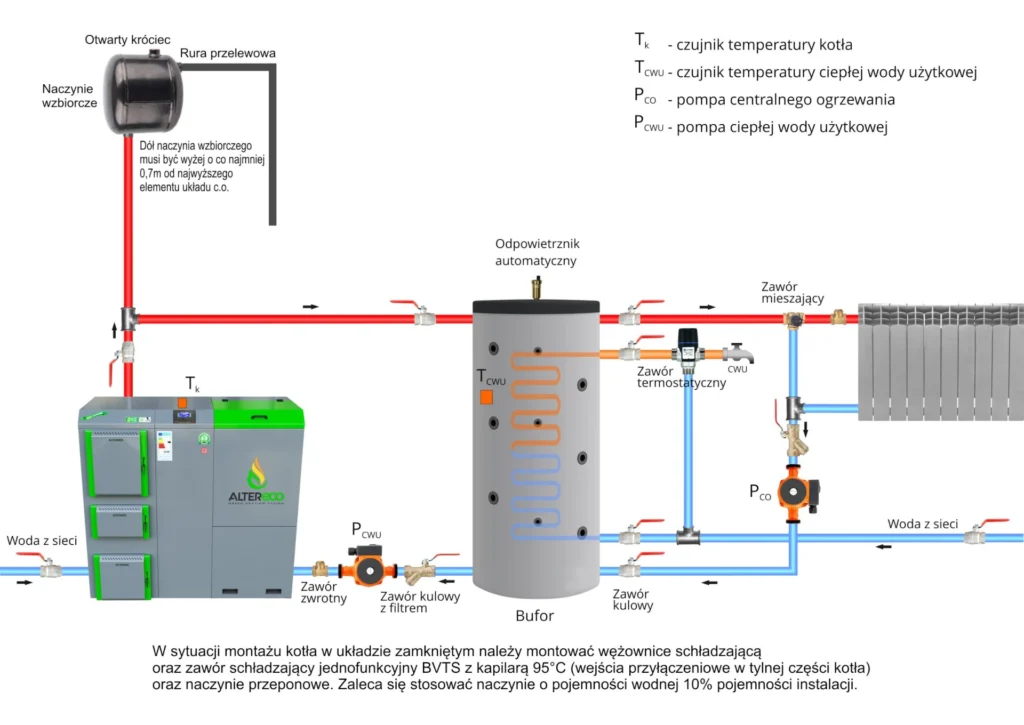

The pump system is slightly more complex but solves the inconveniences associated with gravity. Of course, provided that it is properly installed.

A good example can be found on the Kalvis website (see diagram below). The buffer charging system includes a pump and a thermostatic valve that ensures return protection.

Heating Domestic Hot Water (DHW) from the Buffer Tank

A buffer tank greatly facilitates the preparation of domestic hot water (DHW):

- There is no need to purchase a separate water heater for DHW, which needs to be replaced every few years due to corrosion caused by the constant influx of fresh, oxygenated water.

- DHW is heated through flow – eliminating the issue of legionella.

- During summer, heating the buffer tank to its full capacity ensures hot water for several days.

Heating DHW from the buffer tank is done through a coil, through which cold drinking water flows and heats up from the hot water in the buffer tank. The effectiveness of this process primarily depends on the surface area of the coil. The larger the surface area, the higher the DHW temperature can be achieved even with a lower water temperature in the buffer tank.

Don’t be afraid to push the limits

Before you embrace the buffer tank, reconcile yourself with one fundamental aspect: the buffer tank should be heated to the highest possible temperatures. It may seem obvious, but some individuals install the buffer tank and then hesitate to heat it beyond 50°C. They fear significant heat losses. Not at all!

The buffer tank is intended to be heated to the highest temperatures. That’s why a thick, elaborate insulation is applied to keep standby losses comically low compared to the gains. It’s only our ingrained habits resulting from previous heating patterns that prevent us from fully harnessing the advantages of a buffer tank. The ability to keep boiling water in it for several days is one of those benefits.

Based on: czysteogrzewanie.pl